🚀 Elevate Your DIY Game with Precision Engineering!

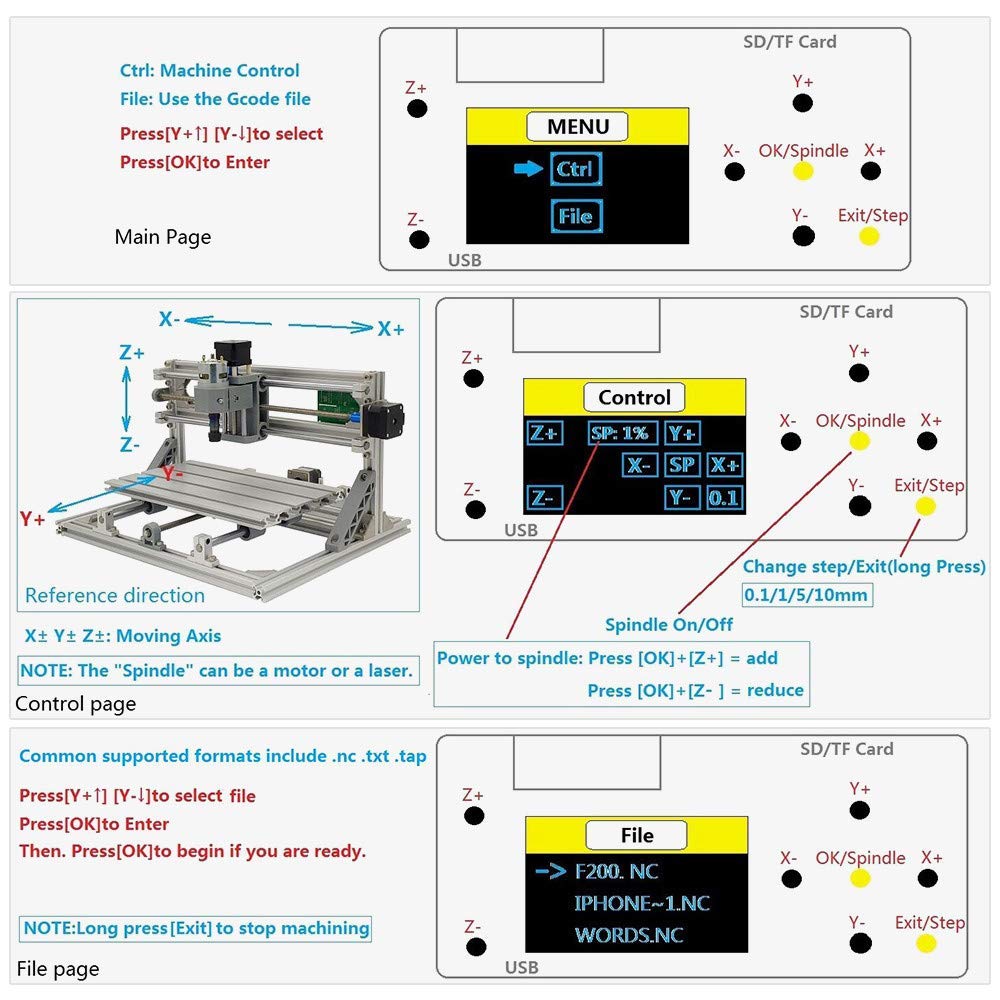

The Vogvigo Upgrade Version CNC 3018 Pro Wood Router Kit is a cutting-edge mini CNC machine designed for DIY enthusiasts and professionals alike. With a spacious working area of 300x180x45mm and powered by GRBL control software, this machine allows for precise engraving on a variety of materials including wood, acrylic, and soft metals. The offline controller offers the convenience of manual adjustments without the need for a computer, while the partially assembled design ensures a hassle-free setup. Backed by a 1-year warranty, this CNC machine is perfect for anyone looking to elevate their crafting and prototyping projects.

| Manufacturer | Vogvigo |

| Part Number | CL-003018JPRO |

| Package Dimensions | 44.7 x 24.6 x 17.6 cm; 6.8 kg |

| Item model number | CL-003018JPRO |

| Colour | 3018 Pro |

| Material | Plastic |

| Power Source | ac |

| Voltage | 24 Volts, 12 Volts |

| Batteries included? | No |

| Batteries Required? | No |

| Battery description | Corded electric |

| Item Weight | 6.8 kg |

J**M

Would definitely recommended but needs a few modifications.

I ordered this unit on the hopes of it being a decent version - you never know what your getting.It arrived well packaged and everything bagged up neatly. Upon removing everything from the package I had to give the extruded rails a wash in the sink as they were full of swarf and cutting fluid - minor issue but I didn't want to get it all.over the kitchen table!Upon laying out all the parts there are no printed instructions included, you simply stick the cd into the laptop and view them on their - my second criticism is that the instructions should have been a pdf file rather than a Word document.I will comment on the fact that the instructions are very clear and concise.. basically consist of pictures showing step by step assembly.Followed the instructions through step by step and after about 1hrs 30mins I finished the assembly. It's a bit fiddly to get table square and in the middle but it's worth doing it properly. The cables are a bunch of single core wires and not a ribbon cable - I have used some super small cable wrap to keep them out from the mechanism!I installed the drivers and the gbrl software and switched the machine on. Scrolling through the options on the add on board and I got it into manual movement and it worked perfectly.Connected to my laptop and at first I could not get it to work with the supplied USB cable (the only one in the box plugs directly into the mainboard not the add on board)... with the add on board connected to the mainboard it refuses to work with it unplugged it's fine - perhaps with the correct cable in the add on board it would that way instead.Clamped down a piece of 6mm MDF and ran one of the test jobs - worked perfectly straight away.The one thing which has been said by other purchasers is the lack of limit switches.. if you get the home zero setup wrong or tell it to move too far then it jams and stalls the motors.. I have switches and will be installing them!So..Pros:1. Straight forward to assemble when following the instructions.2. Very rigid frame and table.3. Worked almost straight away.4. Software included.5. Instructions are clear and concise.6. Includes all the tools needed to assemble7. Includes cutters!Cons:1. Wrong USB cable supplied.2. Needs limit switches.3. The finishing off of parts could be better (swarf and cutting fluid still everywhere).4. Comes with cable ties but needs cable wrap.In Summary? Would I recommend this? Definitely yes! It's a super rigid frame, includes everything you need to assemble it, worked perfectly on the first job, but it could do with a few finishing touches (cable wrap, limit switches etc)

B**4

Good starter CNC machine for hobby use.

I got this Vogvigo CNC 3018 Pro as I wanted to experiment with CNC milling.The kit was easy to assemble following the picture assembly guide on the instruction sheets. Just remember to look carefully at the pictures to ensure you fit everything the correct way round, I made a few blunders and had to refit a couple of items.Once assembled I tested the machine using the local controller, everything moved in the correct directions, so all was good.The main difficulty was getting appropriate software for creating models and sending the resulting g-code to the machine. The machine came with a USB stick with "Candle" on it. Candle can be used to control the machine but does not allow you to design models. After many fruitless days on the web, trying to download Fusion360, for hobby use, I finally gave up and settled for the free to use FreeCad to create models and the free to use Universal Gcode Sender (UGS) to transmit the files to the 3018 pro.It took a few days and lots of trials to come up with settings that actually worked for me., but once found the machine performs really well. It is very noisy, but works well which is the main thing. Quick tip, put some padding under the feet of the machine it cuts down on the vibrations considerably.I have managed to cut and profile 4mm clear acrylic. My first attempts were disasterous with the acrylic melting on the bit, this was caused by setting too slow spindle speed and traverse speed, allowing the bit to heat up and melt the acrylic., which sadly stuck firm to the bit.Finally I settled on using• cutting and profiling with the 3mm end mill that came with the kit• horizontal feed set to 1000 mm/min in freecad• vertical feed to 300mm/min in freecad• spindle speed 1000 in freecad which equates to 100%• step down set to 0.5mm any more and the spindle stalled. so cuts take a few passes to reach the final depth.Using the PATH workbench on FreeCad I then set the various machining paths (jobs) before post processing to gcode, in FreeCad, to a file "*.nc" compatible with the universal gcode sender program. This process took some time to figure out, with watching many videos, internet searches, and experimentation. I found it best to ensure the top face of the job models were on the z axis, with the main body below. Then when you set zero on the 3018 pro ( via UGS) to the top of the workpiece everything works fine.The machine as delivered does not have any limit switches, and if you send the spindle outside its area you will be rewarded with an awful grinding noise as it reaches the hard stops. Personally I will add limit switches in time, but at present as long as you are careful with the design they are not needed.I have attached some pictures of the acrylic pieces I have cut. Only little test pieces so far but very impressed with the results.I aklo tried engraving with the supplied Vbits, again you need to experiment with the settings, but initial results are good.In summary, very impressed with this machine and would recommend for hobby use. It would of got five stars if it came with design software or even good tutorials for using the likes of FreeCad and Universal Gcode Sender.

A**R

A good introduction to CNC

I'm really pleased with this machine.It arrived well packed and everything needed for assembling it was included, all Allen keys necessary and spanners for the ER13 collet (which was pre fitted) The control board has a cover and is fitted with a cooling fan. The power supply was supplied with a Euro plug, which was no good for me in the UK, but the 2 pin socket into the power supply is a very common one and I already had a suitable power lead.The pictorial instructions were clear and I had little trouble assembling the machine except for 3 of the tapped threads which needed de-burring before the screws would go through them (I recommend trial fitting screws into all the tapped threads BEFORE assembly to make things easier if any need de-burring).The software is on a CD, was virus-free and installed OK. Everything worked OK in the test files supplied wih the kit although the offline controller is a little 'clunky' to use, so I've used the machine directly connected to my computer for most of the time.The clamps supplied are a bit fiddly to use, but they do work. I haven't used the supplied engraving cutters much but they seem OK. The supplied endmills are of variable quality, the grinding on them seems to vary from cutter to cutter. That said, I've used them to cut through 6mm plywood and 10mm mdf without any problems and they produce a very accurate result.I'd recommend this machine as a good value, low cost inroduction to cnc.

Trustpilot

2 weeks ago

3 weeks ago