Entregar a Argentina

IPara la mejor experiencia Obtener la aplicación

Servicios al cliente

Sobre nosotros

Copyright © 2024 Desertcart Holdings Limited

⚡ Elevate your projects with the powerhouse of insulation & durability!

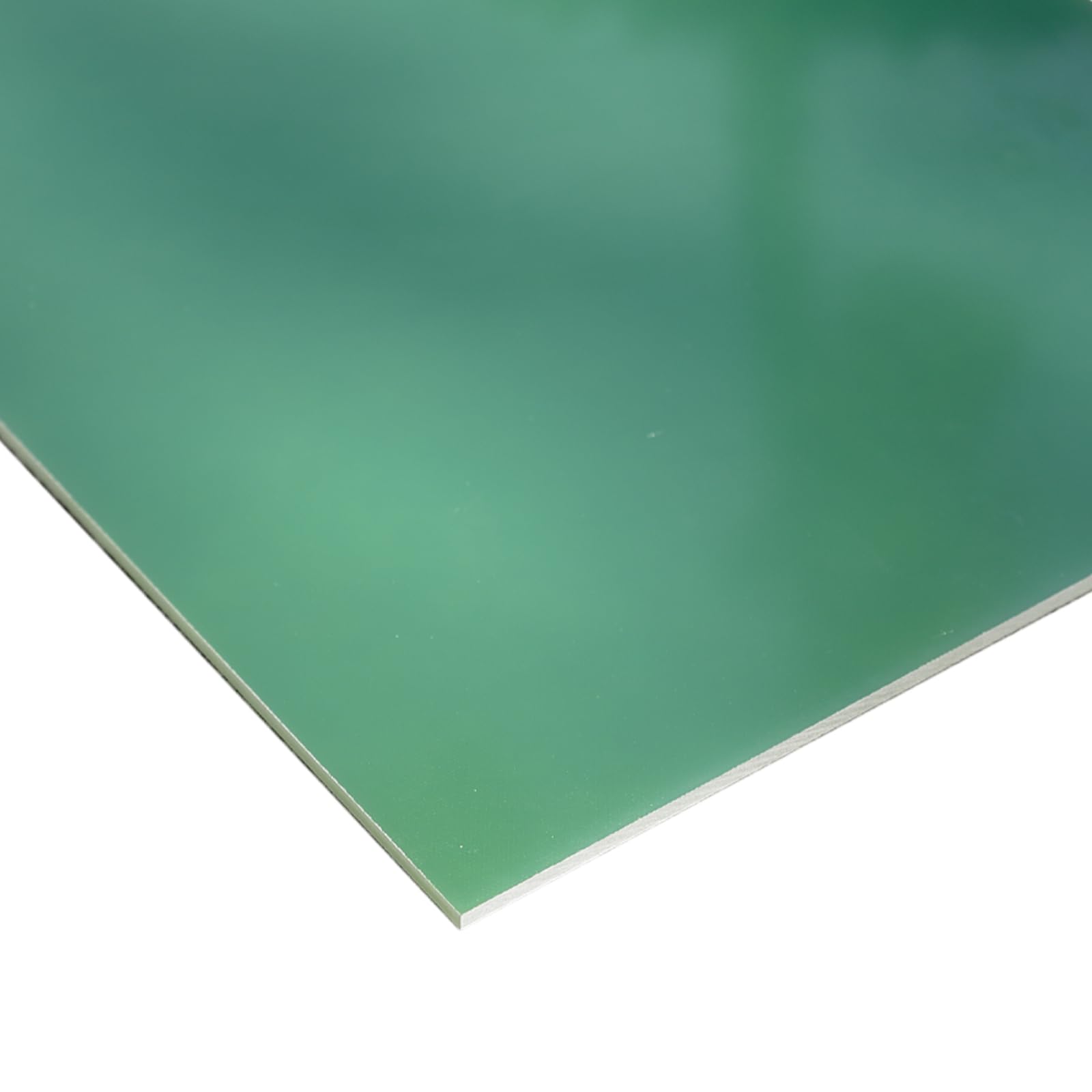

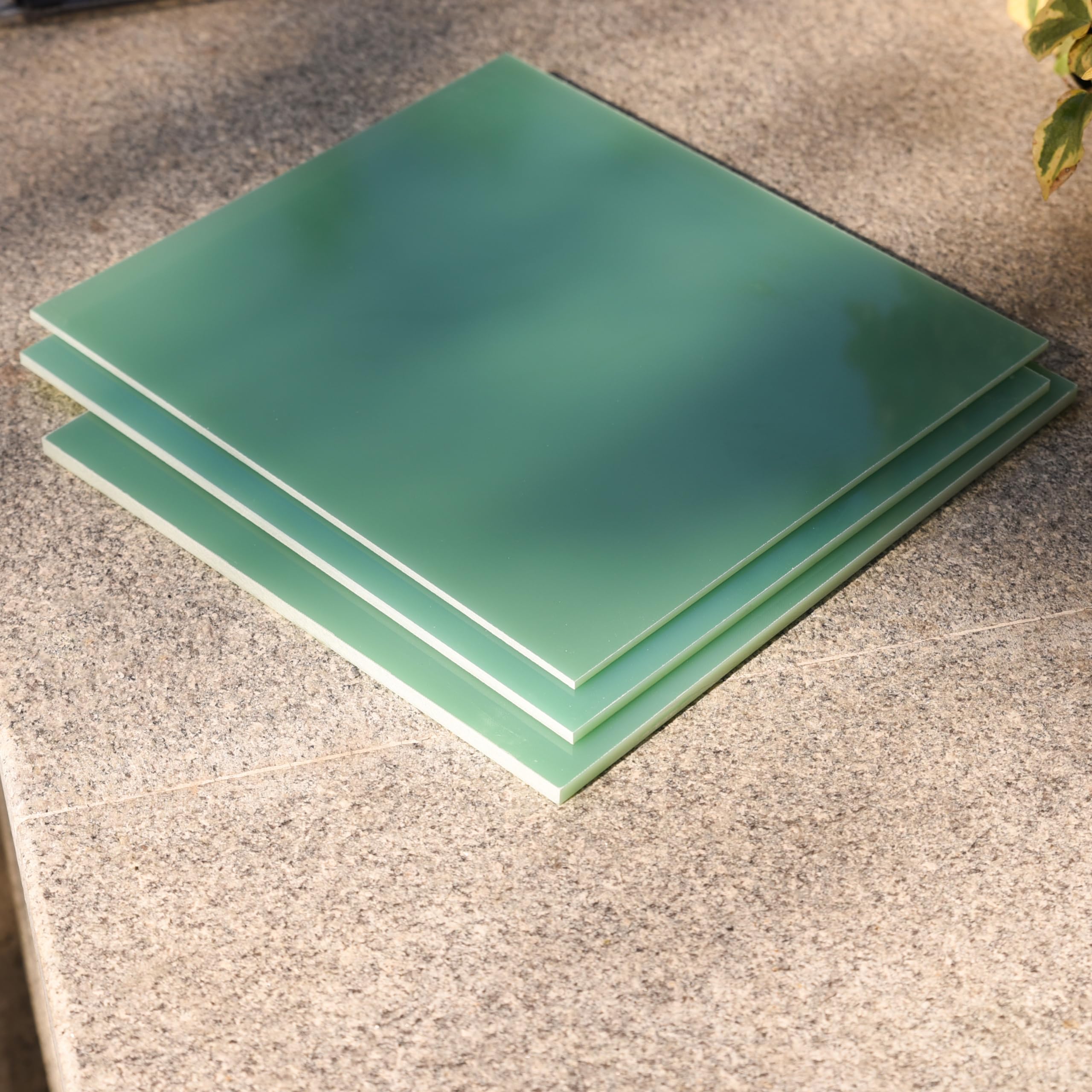

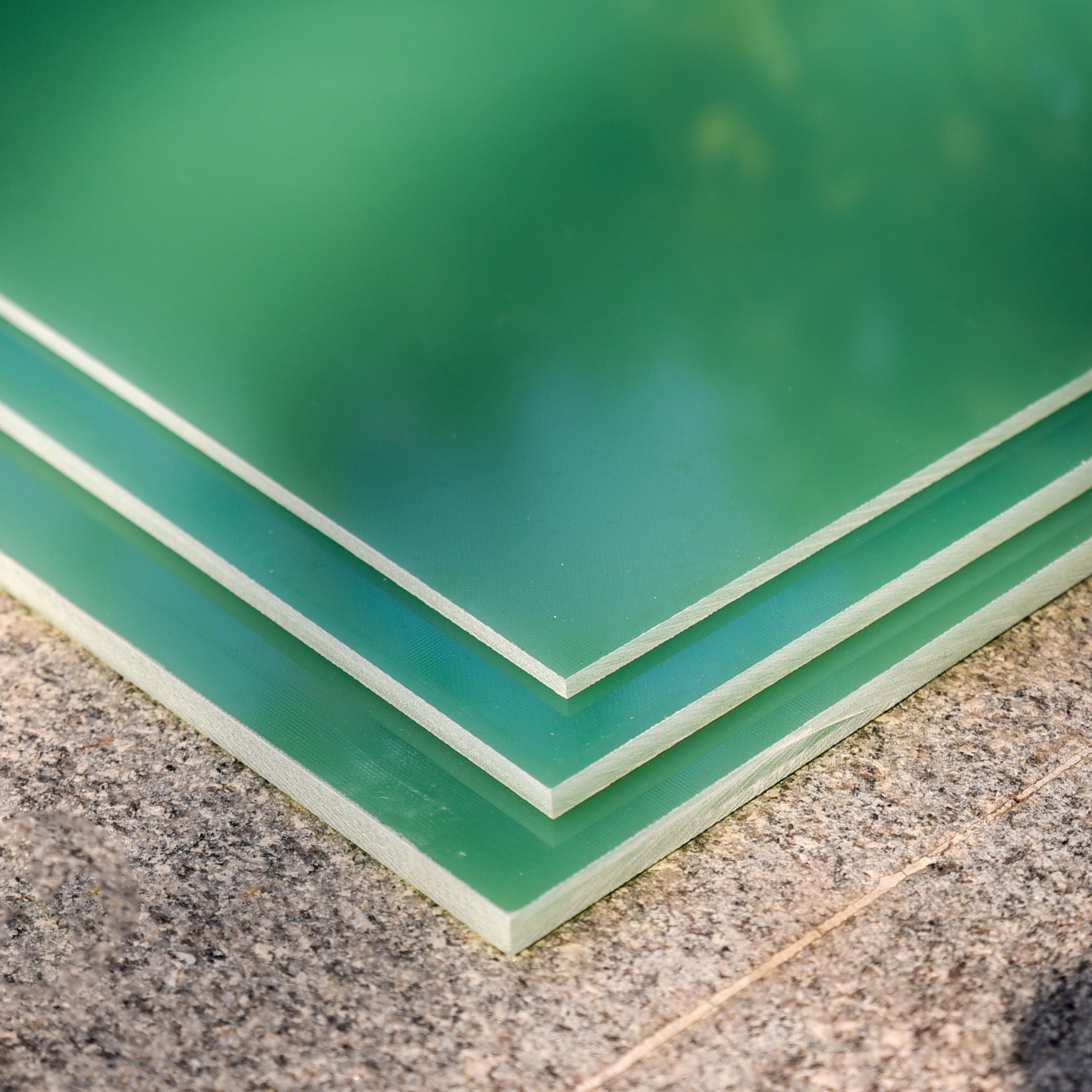

This FR4 Epoxy Sheet (335×300×6mm) is a flame-retardant, high-temperature resistant, and physically robust insulation plate widely used across advanced industries like aviation, rail transit, and electronics. Its industrial-grade quality and precise dimensions make it indispensable for manufacturing high-performance electrical and mechanical components.

| Item Thickness | 1E+1 Millimeters |

| Item Form | Sheet |

| Grade Rating | Industrial |

| Number of Items | 1 |

| Manufacturer | Ciwenkai |

| Item Weight | 2.97 pounds |

| Product Dimensions | 13 x 11 x 0.4 inches |

| Material Type | FR4 Epoxy |

| Size | 335×300×6mm |

| Manufacturer Part Number | 2356476 |

Trustpilot

Hace 3 semanas

Hace 1 mes