Entregar a Argentina

IPara la mejor experiencia Obtener la aplicación

Servicios al cliente

Sobre nosotros

Copyright © 2024 Desertcart Holdings Limited

🔇 Silence the road, feel the difference.

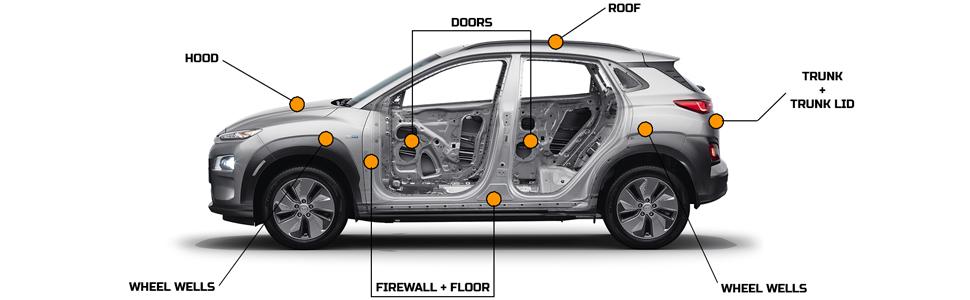

The Siless Hybrid 3in1 200 mil Car Sound Deadening Mat is a premium 25 sqft automotive soundproofing solution featuring a thick triple-layer composite of butyl mastic, PE foam, and mass loaded butyl membrane. Designed to reduce low-frequency noise, vibrations, and exhaust heat, it installs easily with a peel-and-place method—offering professional-grade noise insulation and heat blocking at a cost-effective price.

| Manufacturer | Bema Group Inc. |

| UPC | 094308950341 |

| Part Number | SLH20025 |

| Item Weight | 17.83 pounds |

| Product Dimensions | 15.39 x 9.76 x 0.04 inches |

| Item model number | SLH20025 |

| Size | 25 sqft |

| Item Package Quantity | 1 |

| Coverage | 25 sqft |

| Batteries Included? | No |

| Batteries Required? | No |

M**H

Works well and is easy to install.

I was sound and heat insulating a generator bay in my class A RV so I did three tests before and during material application: I did a sound level test to see how effective the material was for my application, a "stickiness" test, and a flammability test. This was indoors on a dry 78°F day. From beginning to end, the entire process, including testing, took 5 hours to install 25 sqft or material in a very complex area. One hour for cleaning, 3 hours for installation, and 1 hour for test setup and testing.Using a sound meter, I took before and after readings and determined that I reduced the sound level by 2.2 db (40% energy decrease) with a noticeable decrease in sound and frequency. The generator bay is located under the master bedroom in the aft portion of the coach. The sound went from a rattling, vibrating generator noise to a more tolerable low level rumble.The material was easy to apply. I did some testing prior to application and determined that surface preparation is key. I cleaned my painted metal surface and then degreased with acetone and the material stuck well. Be careful and purposeful when you apply the material because once it was stuck to the metal, it was quite difficult to remove or reposition.Since it was going to be installed into a gasoline powered generator bay located under our sleeping quarters, I did some flame testing to determine the level of risk. Although not highly flammable after installation, my testing revealed that the PE used will catch on fire under certain circumstances. In order to reduce the risk, I used aluminized duct tape to ensure that all the edges were sealed and the PE was not exposed to direct flame in the event of a fire. I also decided to install an automatic fire extinguisher as an added precaution. In all fairness there should be one installed in the generator bay anyway.All in all, I am very satisfied with the product and the results. I have recommended this product to my other RV owner friends.

E**A

I wish I had Siless 20 years ago!!!

I have installed all kinds of insulation in vehicles over many years. I only needed to purchase 2 boxes to complete the entire interior siding of my 2025 chevy express, what a great value! I wanted to insulate my locksmith van for sound and heat. The sound reduction virtually eliminated the road noise. These panels also look amazing. It got up to 110F in the sun with the doors closed. After adding Siless insulation the temperature maxed out at 97F. That is a massive difference. Plus, I didn't even finish with the roof before testing. Siless Hybrid 3in1 was extremely easy to cut and adhere onto metal panels. I'm impressed with the quality of the individual panels and the adhesive is not toxic smelling compared to some others. My favorite thing about these panels is you can actually take them off and readjust them before they finally stick and they do not leave any black residue behind when you pull them up to adjust them. All I needed was a heat gun, knife and a roller to complete this job. The size of each panel is perfect, you can handle them with ease. I probably won't need your product again for a while, but when I do I will definitely be back.

J**N

Very good product. Road/tire noise is pretty much non-existent

I really like this stuff for the added sound insulation. MLV is great for reducing resonance, but it really doesn't add any insulation from road noise etc. I installed three boxes of this in my Tacoma. Floor, doors, rear cab panel, roof. It is amazing how much quieter it is in the hwy. Road noise is pretty much non-existent . It also did a great job on the doors for my sound system to reduce resonance and buzzes. It is not quiet as good as the Siles butyl deadner for isolating and removing panel resonance, but I think the reduction of road and tire noise is well worth the trade off. There are many people who use this over the butyl, which I'm sure is just amazing!

A**T

Outstanding Noise Insulation with Hybrid Layering Design!

I recently installed the Siless Hybrid 3in1 200 mil sound deadening mat in my car, and I’m genuinely impressed with the quality and performance. The unique layering design, especially the second layer, provides superior sound insulation and vibration dampening. The butyl rubber layer is thick and adheres well to surfaces, creating an effective barrier against road noise and vibrations.Applying this mat was straightforward, and the flexibility of the material made it easy to install, even in tight spaces. After installation, I immediately noticed a reduction in noise, making my car much quieter and more comfortable. This product is perfect for anyone looking to upgrade their vehicle’s soundproofing. Highly recommended!

S**Y

Great stuff

Bought 2 cases of this to do the side walls and roof of the interior of my chevy express. Its really good stuff.. goes on easy. I like the size of the tiles.Huge bit of advice is keep them out of direct sunlight when installing and try to do it below 65 degrees I would say. It got up to about 70F and the adhesive got pretty tackie and hard to peel from the backing.Sound and insulation wise.. it does make a difference with sound. Going down the road it really makes my van smooth. Insulation from temp though we’ll have to wait until the summer to see

Trustpilot

Hace 2 días

Hace 2 meses